Product features

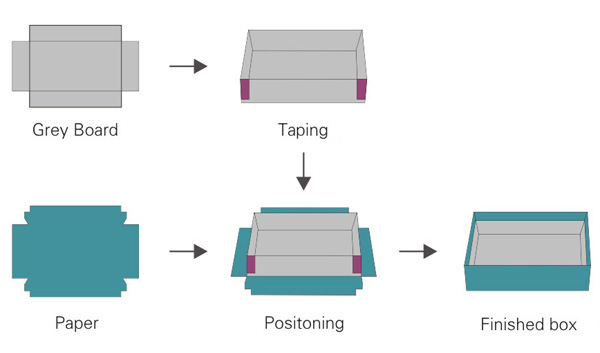

ZS-6418 intelligent automatic rigid box making machine is composed of automatic feeding & gluing machine, automatic tapping machine, automatic positioning machine and automatic forming machine, it’s the most advanced rigid box making machine till now.

1.High automation, greatly save labor and increase efficiency.

2.Adopts motion controller and touch screen type man-machine control system, simple operation, easy to learn.

3.Rational structure, low fault rate, with automatic fault alarm and trouble shooting.

4.Humanized design, convenient and quick mold changing and adjusting.

5.With memory function, can save and recall settings.

6.24 hours timing control glue heating function.

7.Servo optical fiber positioning system, high positioning accuracy ( ±0.2mm ).

8.Servo control spindle push box down onto surface paper, stable and accurate.

9.Robot arm automatic pick up and draw box, avoid scratch.;

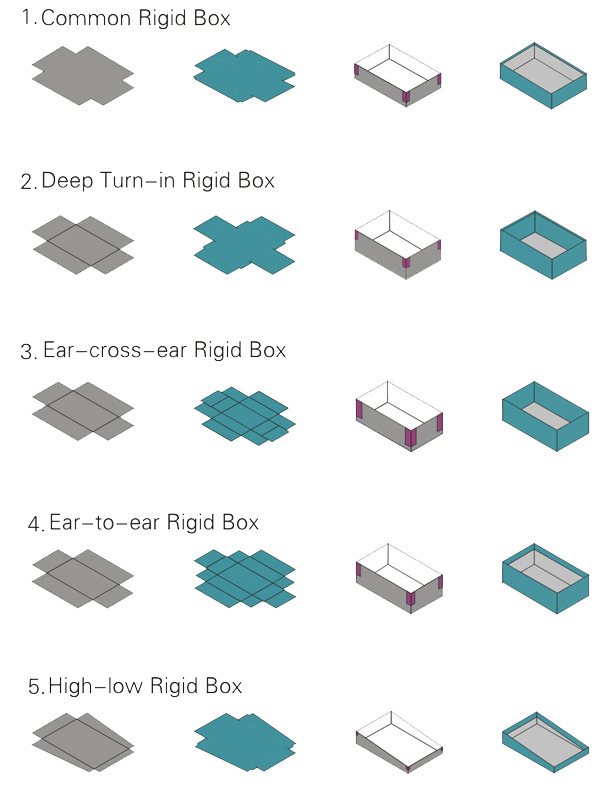

10.Servo control box forming, the four heads can work independently, suitable for various styles of box.

Product application

Widely used in gift boxes, moon cake boxes, mobile phone box, shoes box, watches, jewelry box, cosmetic box, tea box, wine box, medicine box, etc.

Jewelry box

Jewelry box

Shoe box

Shoe box

Gift box

Gift box

Mobile box

Mobile box

Cosmetic box

Cosmetic box

Product parameters

| Model | ZS-6418 | |

Paper size | W min | 95mm |

| W max | 610mm | |

| L min | 180mm | |

| L max | 920mm | |

Paper thickness | 80-300g/m2 | |

Cardboard size | W max | 580mm |

| L max | 920mm | |

Cardboard thickness | 1-3mm | |

Finished box size(W*L*H) | L min | 100mm |

| L max | 600mm | |

| W min | 60mm | |

| W max | 400mm | |

| H min | 12mm | |

| H max | 120mm | |

Turn-in paper size | R min | 15mm |

| R max | 90mm | |

Ear cross ear folding size | L max | 150mm |

Positioning accuracy | ± 0.15mm | |

Production speed | 1 time molding | 25-30pcs/min |

2 times molding | 23-25pcs/min | |

3 times molding | 20-23pcs/min | |

4 times molding | 18-20pcs/min | |

Air pressure | 6-8bar | |

Glue tank capability | 50kg | |

Motor power | 22kw/380v 3phases | |

Heater power | 6kw | |

Machine weight | 5800kg | |

Machine dimension | L7000×W4200×H3250mm | |